The Essential Guide for Conveyor Case Chain

Conveyor case chains are essential elements in the realm of material handling solutions. Their primary function is to transport various goods across factories, warehouses, and manufacturing facilities efficiently. Engineered for strength and precision, these chains are designed to ensure operational smoothness even in high-demand scenarios.

Key Characteristics of Conveyor Case Chains

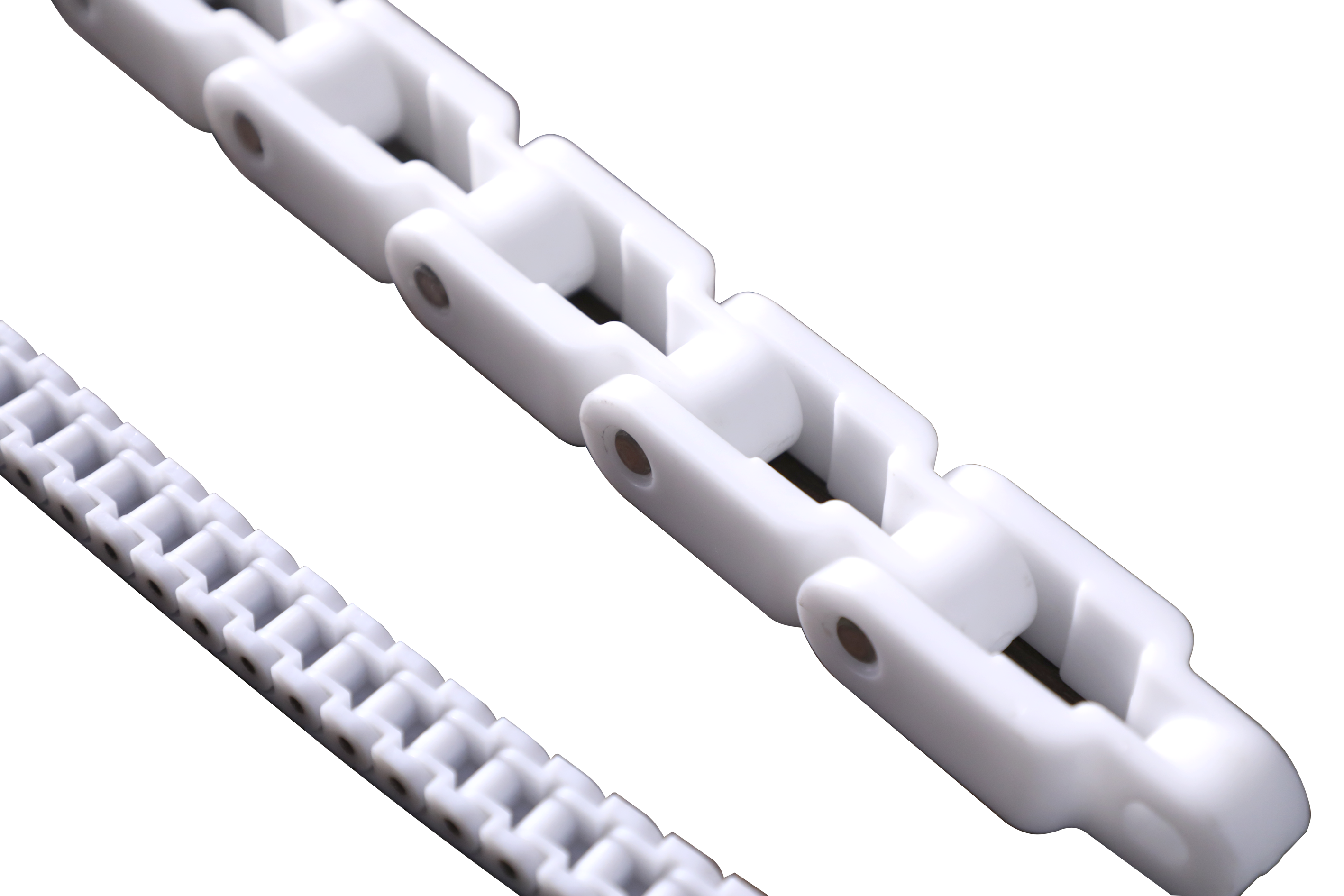

Robust Construction

Conveyor case chains are constructed from high-quality materials such as stainless steel or reinforced polymers, which significantly enhance their lifespan and decrease the likelihood of wear and tear.

Seamless Operation

Through advanced engineering techniques, these chains guarantee smooth movement, which effectively reduces friction and enhances energy efficiency.

High Load Capacity

These chains can manage substantial loads, rendering them perfect for sectors such as automotive manufacturing, packaging, and logistics.

Customizable Designs

With a range of sizes and configurations available, conveyor case chains can be customized to meet specific operational requirements.

Advantages of Using Conveyor Case Chains

Improved Efficiency

The implementation of conveyor case chains enhances productivity by ensuring continuous material flow.

Cost-Effective Solutions

These chains significantly cut operational fees by minimizing downtime and lowering maintenance needs.

Broad Applicability

They are versatile enough to be implemented across numerous industrial environments with relative ease.

Common Uses of Conveyor Case Chains

Industrial Manufacturing

Within production facilities, conveyor case chains are crucial for assembling and relocating components along production lines.

Warehouse Logistics

They enhance inventory management by automating the movement of materials between various sections.

Food and Beverage Sector

The hygienic design of these chains makes them suitable for the safe transportation of food-grade items.

Selecting the Appropriate Conveyor Case Chain

Material Choice

Select materials that align with your operational needs, such as corrosion-resistant steel for moist environments.

Assessing Load Capacity

It is crucial to ensure that the chain can meet the weight and volume demands of your system without compromising efficacy.

Maintenance Considerations

Opt for chains that require minimal maintenance to limit operational disruptions.

Care Guidelines for Conveyor Case Chains

Regular Checks

Conduct periodic inspections of the chains to detect wear and replace any damaged parts.

Lubrication

Utilize suitable lubricants to reduce friction and extend the chain's lifespan.

Tension Management

Proper tension adjustment is essential to prevent slippage and ensure optimal functionality.

Final Thoughts

Conveyor case chains are key contributors to enhancing efficiency in industrial settings. When selected and maintained correctly, they promise durability and optimal performance across various industries. Investing in high-quality conveyor case chains is essential for achieving operational excellence.

For further information, please visit www.pathtechco.com

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0